News

-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Here you meet us:

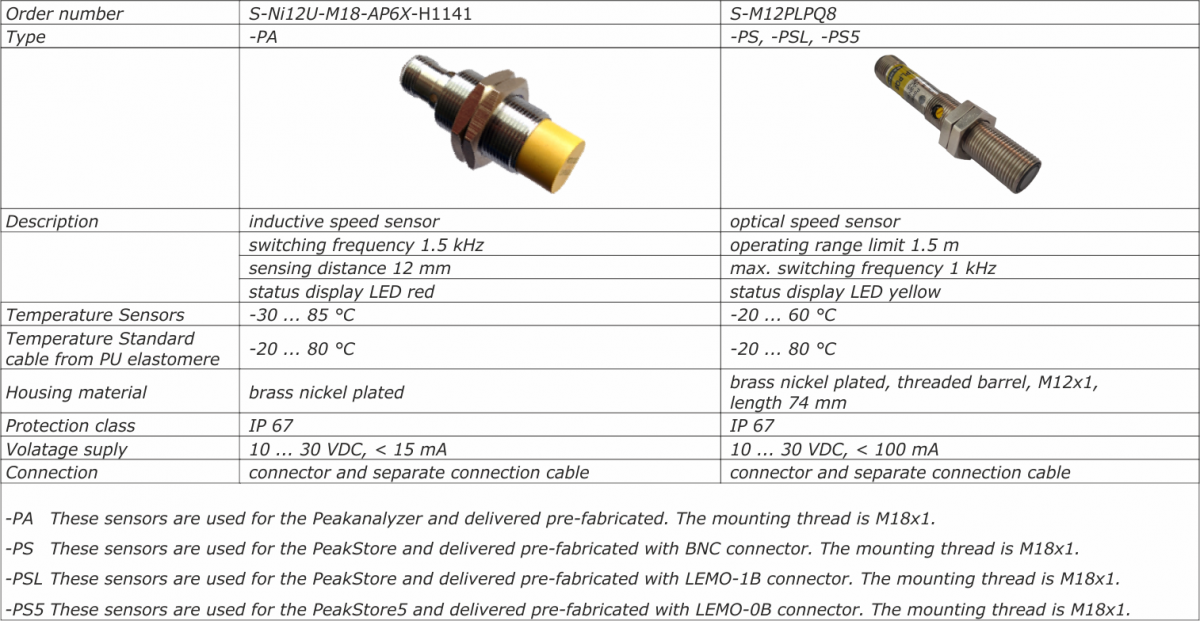

Speed Sensors

Speed sensors either operate optically or inductively. Optical sensors are commonly used for offline measurements. Then, you usually need a reflection mark on the shaft. The passing of the reflection mark is registered by the sensor. Inductive sensors register the passing of metallic objects. This may be the screws of a coupling.

In general, the high-speed shaft is used for the speed detection of the drive. For order analysis, it is enough to detect the speed at least once per revolution. Therefore, one measurement point on the rotating shaft is sufficient.

A construction aid is needed to attach the speed sensor. This has to be customized for the drive.