-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Field balancing with the PeakStore5

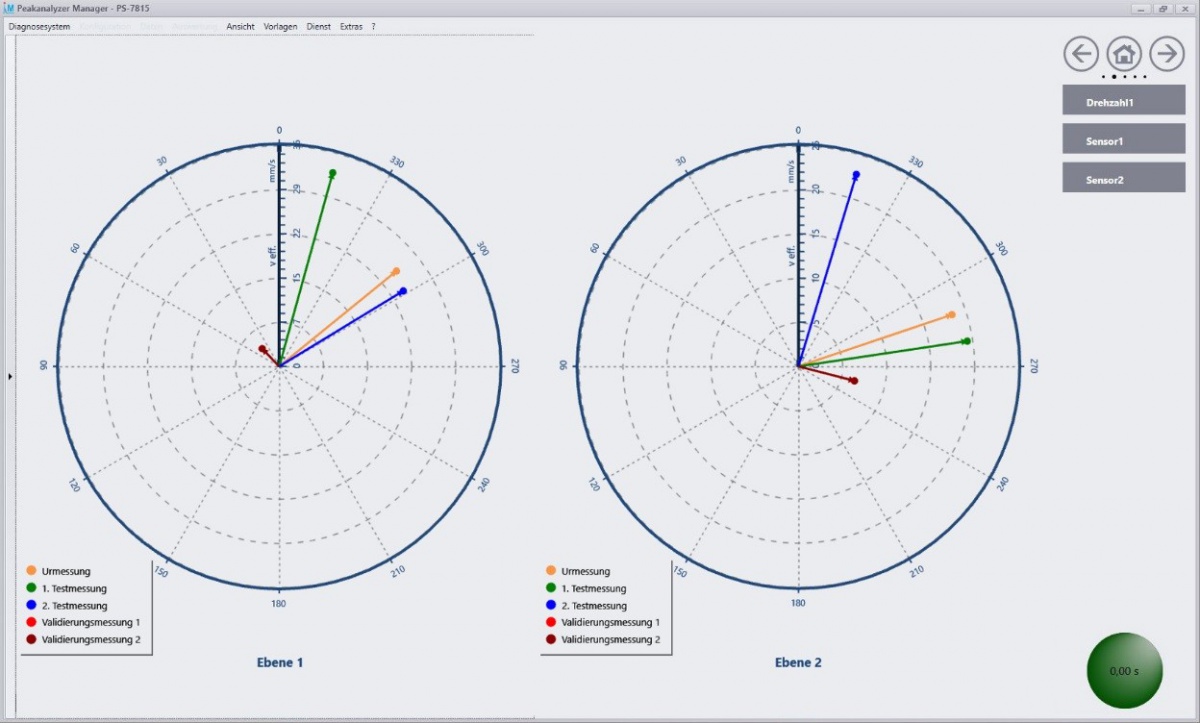

The field balancer module is available as a separate license option for the PeakStore5. In this case, the vibrations caused by imbalance are measured on a fully assembled rotor and calculated required balancing weights. This is done in one or two balancing planes and at variable speed.

The process is simple

The two balancing planes are defined. Two accelerometers and a rotary encoder are installed. First, then a Urmessung is performed. At a compensation level, a test mass is applied and a first test measurement is performed. Thereafter, this process is repeated for the second level of compensation. Based on this data, the system calculates the balancing weights and locations of attachment. The system takes into account that the application of balancing weights is only possible at certain radii or angles or that masses should not be added, but removed. Up to five validation measurements are possible to progressively minimize the imbalance. Finally, a log is generated that documents the entire process and specifies the balancing quality according to DIN ISO 21940-11: 2017-03.