-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

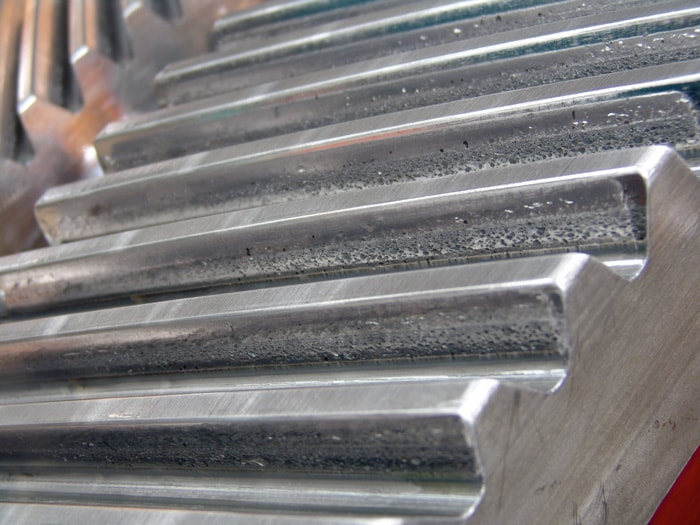

Gearbox Inspection and Video Endoscopy

You would neither expect the owner nor the operator of a production plant to have that deep technical knowledge of all system components. Therefore, it is absolutely normal to involve specialists. So it is also with mechanical power trains, especially with gearboxes. The detection and evaluation of damages on gears as well as the derivation of specific recommendations for further operation and maintenance is part of a major service in great demand.

The gearbox inspection consists of the evaluation of

- the external condition of a gearbox, the detection of leaks, problems related to the fundament and thermal anomalies,

- the function of the lubricant,

- the tooth mesh on the basis of the visible tooth flanks and

- the accessible bearings.

For the inspection, the drive must be switched off and secured against movement. Then the inspection covers are opened. Now our specialist has a close look on viewable parts directly or by means of a video endoscope. The gearbox inspection should be combined with the vibration diagnosis, because:

- Although the inspection offers advantages in the evaluation of damage type and damage size on tooth flanks, it is limited to the currently visible teeth. In contrast to this, the vibration diagnosis provides statements to all teeth, but with less resilient results according to the damage size.

- The inspection provides definitive statements about the type and the size of damages, if they can be viewed directly or with tools. With the vibration diagnosis all race ways and rolling elements are necessarily analysed.