-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Bucket-Wheel Excavators and Stackers in Surface Mines

In mines, there are impressive machines that do complex work under adverse climatic conditions. Bucket-wheel and bucket-chain excavators run with low speeds. Performance and speed as well are characterized by discontinuity due to the process. Conveyors are several kilometers long and overcome differences in height, leading to dynamic influences.

Although these machines are fully developed and tested, there occur problems as well. To detect arising damages on rolling bearings and gears the vibration diagnosis is suitable. This can be done by an offline measurement or by means of online condition monitoring systems.

Also completely unexpected problems can be quickly limited by using vibration measurements, if necessary in connection with torque analyzes. Therefor the GfM offers the service "Troubleshooting " as a product.

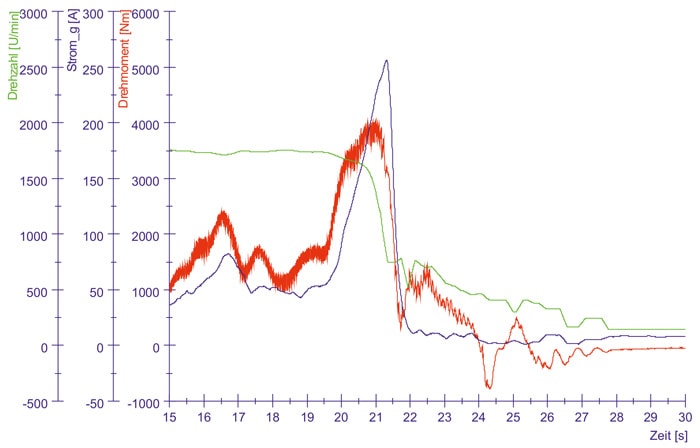

Measurement results at shutdown a bucket show

- The motor current goes rapidly to zero.

- The speed goes lower to zero.

- The torque includes a high frequency har-monic and achieves negative values several times, which indicates a commuting, therefore, a repeated load reversal.