News

-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Here you meet us:

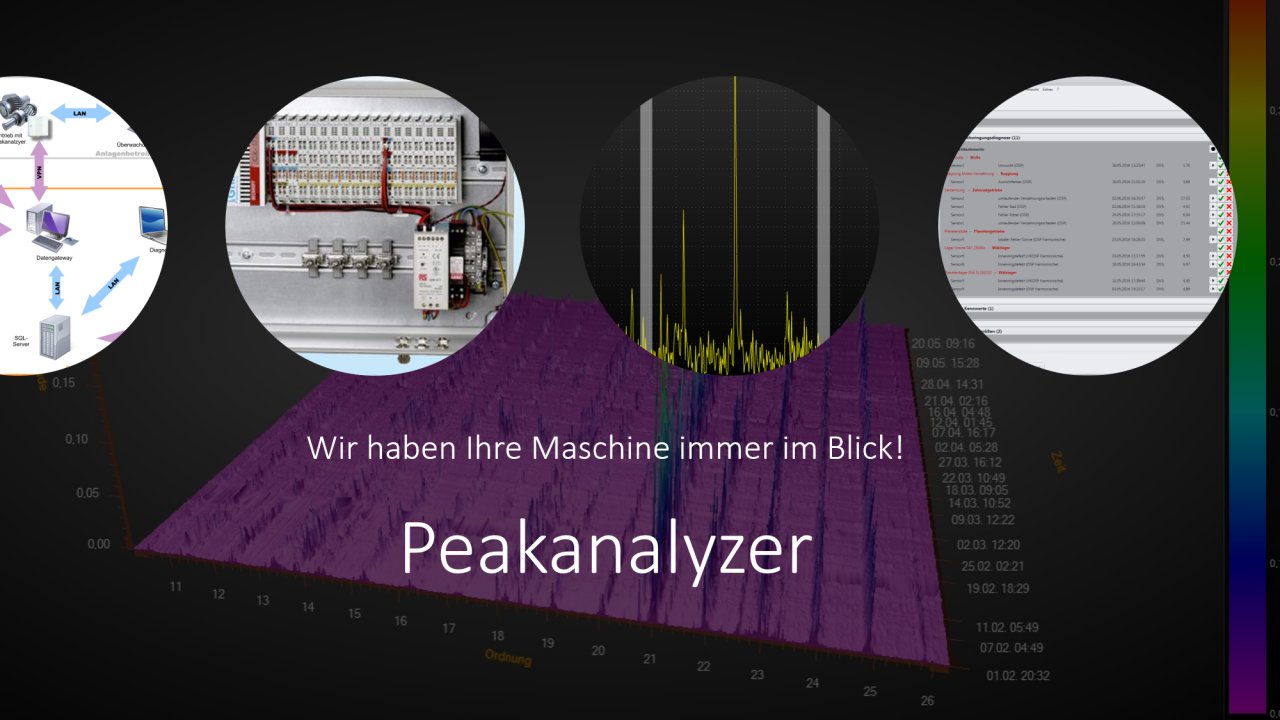

Installation, Configuration and Commissioning

The installation of the accelerometers is very easy. For each sensor, a small mounting base is glued on the machine. The sensor itself is screwed. Now, the sensor cables are connected to the Peakanalyzer. The power supply and a network cable is connected, too.

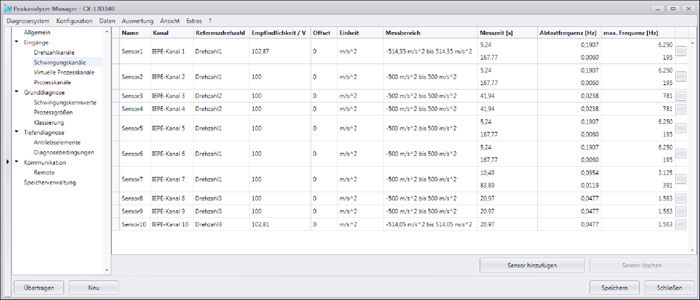

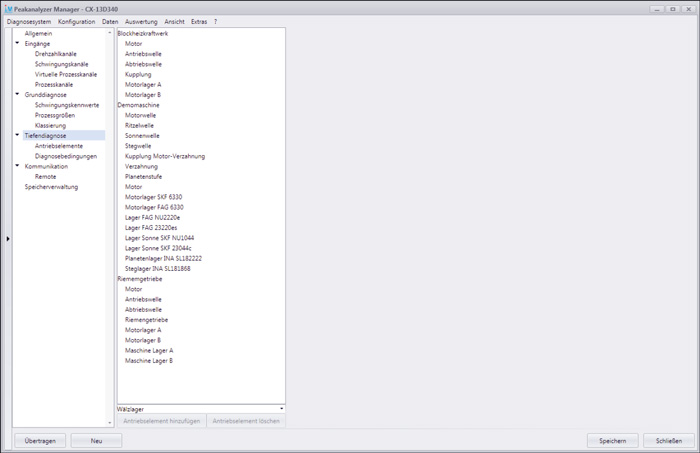

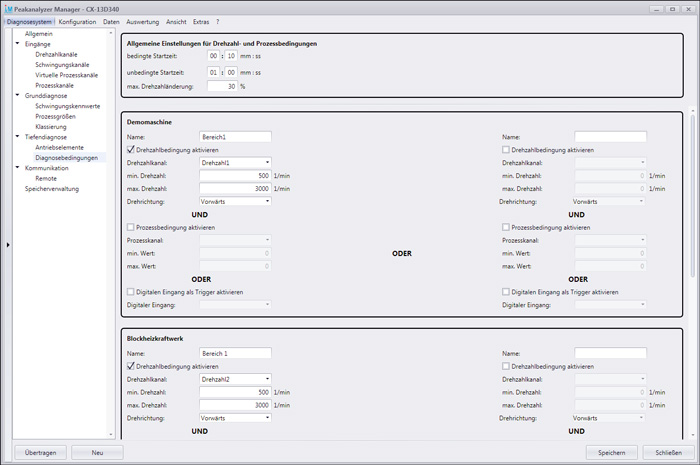

The Peakanalyzer has to be supplied with some basic information. These are the kinematic data of the drive and a few fundamental definitions. The correct connection of all sensors can be checked again. The relevant menus are avail-able. Thereafter, the Peakanalyzer can be put into operation, immediately. Now, the system starts the monitoring.

Recommended positioning of accelerometers:

- Motor B-bearing: radial

- Motor A-bearing: radial and axial

- Planetary gear stage: drive end and output side, radial

- Cylindrical gear stage: drive end and output side, radial

Check the sensors