-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

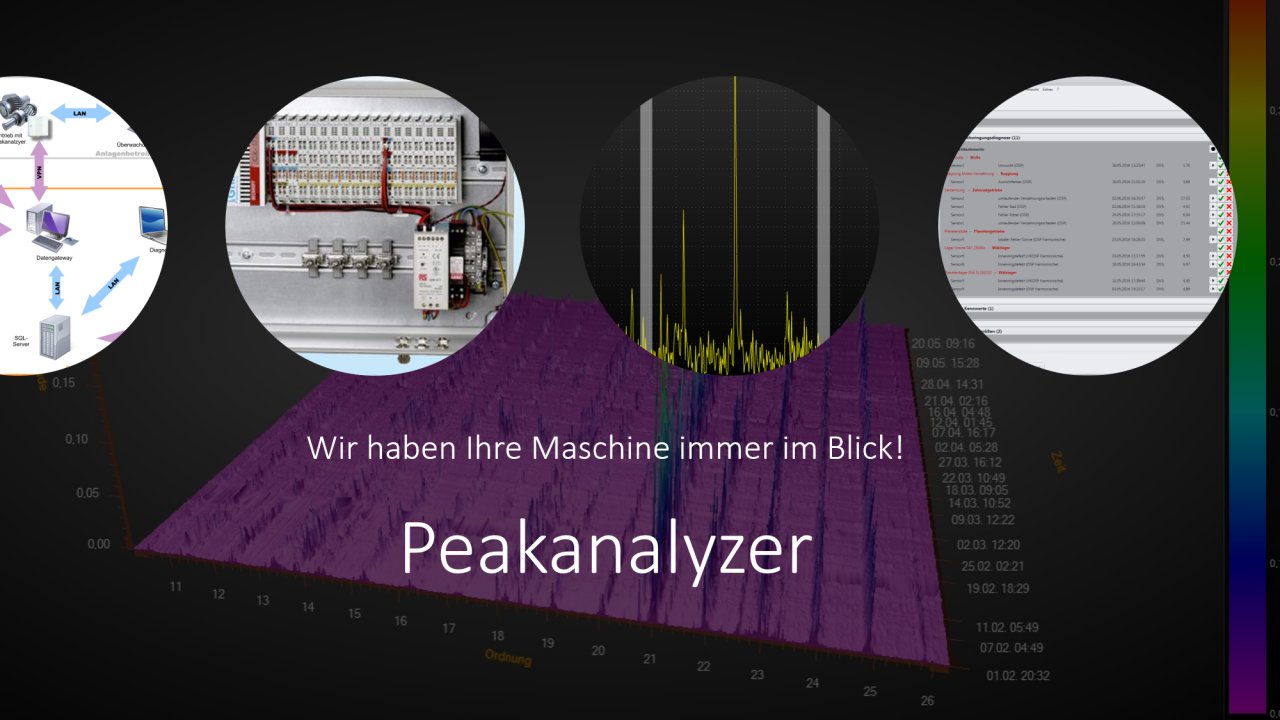

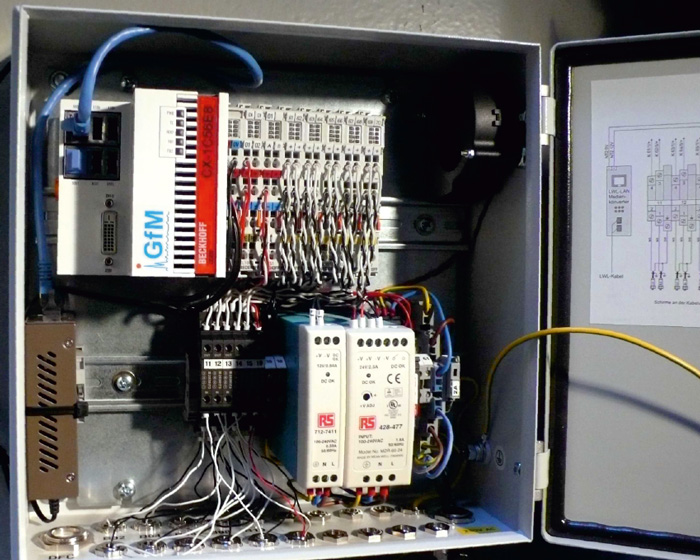

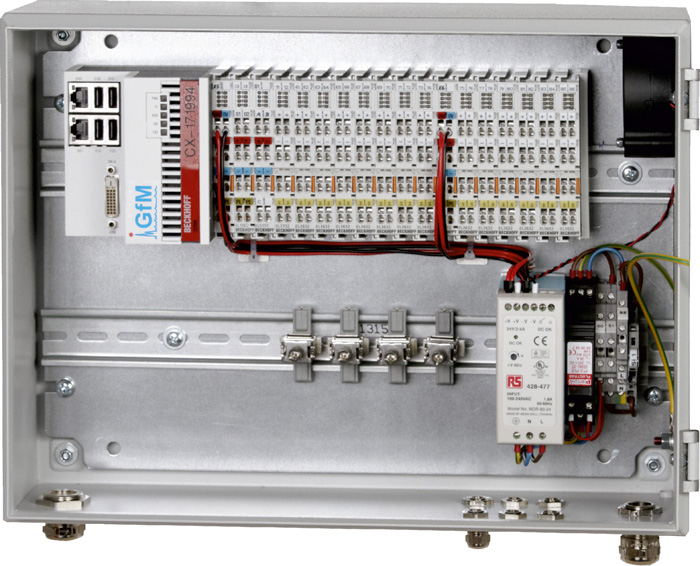

Peakanalyzer – the Fully Automated Online Condition Monitoring System

The Peakanalyzer monitors the vibrations of a drive, fully autonomously. Spectra and envelope spectra are composed of the measured time signals. These spectra will be analyzed regarding to pattern, that are typical for damages on drives. And if this is the case, the system generates an alarm. So far, no action is required.

The alarm includes a plaintext, that describes the detected irregularity in a simple way. This is the first time, a human action is required to confirm the alarm.

If the Peakanalyzer has detected a typical damage pattern and has generated an alarm, then there is still enough time until the actual breakdown of the drive. In general, you will observe the “growth” of a damage, while organizing the maintenance works, simultaneously.

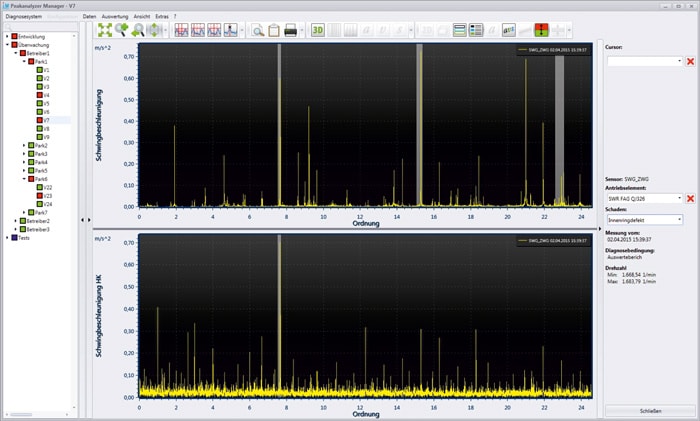

Except for the very meaningful plaintext, there is also the opportunity to see all the data, that led to the alarm. These are spectra and envelope spectra, waterfall displays and spectrograms or just the profile of the amplitude of a particular frequency line as a time plot. So diagnosis experts can contribute their specific experiences.

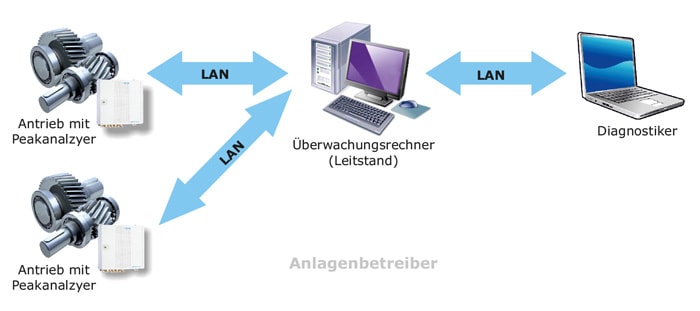

The plant operator can supervise the Peakanalyzer, himself. Alternatively, GfM can be mandated with the supervision or also a independent third company.

Damages that can be reliably detected by the Peakanalyzer:

- roller bearing defects

- irregularities of gears

- failures on shafts

- imbalances

- alignment failures

- other irregularities

High diagnostic reliability through innovative algorithms

On the one hand, no damages on gears have to be overlooked. On the other hand, the system should not be too sensitive, that false alarms are generated, permanently. Therefore, very intelligent algorithms are applied to perfect the diagnosis:

- Reliable diagnosis in case of speed variations by the consistent use of order analysis

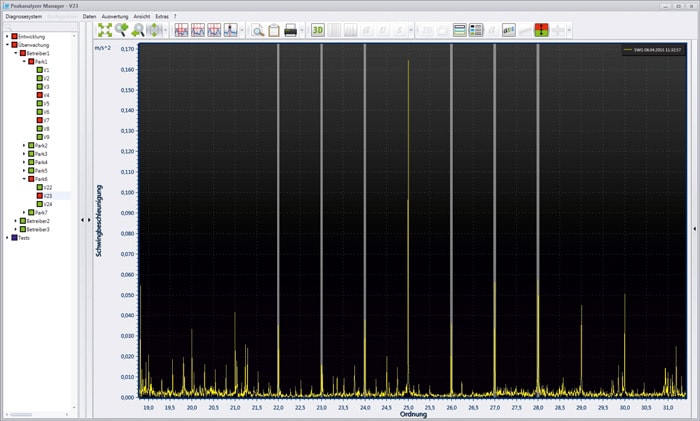

- Formation of high-resolution spectra with 32,768 lines to avoid diagnostic errors due to low spectral resolution

- Reliable diagnosis in case of unknown machine load by the use of DVS-analysis of all spectra

- Reliable diagnosis in case of coincidental match by the use of cross-checking of symptoms of damage frequencies

- Reliable diagnosis in case of undefined operating conditions by automatic verification of valid diagnostic conditions

- Reliable diagnosis in case of coincidental transmitted vibrations by verification of alarms in subsequent measurements coincidental transmitted vibrations

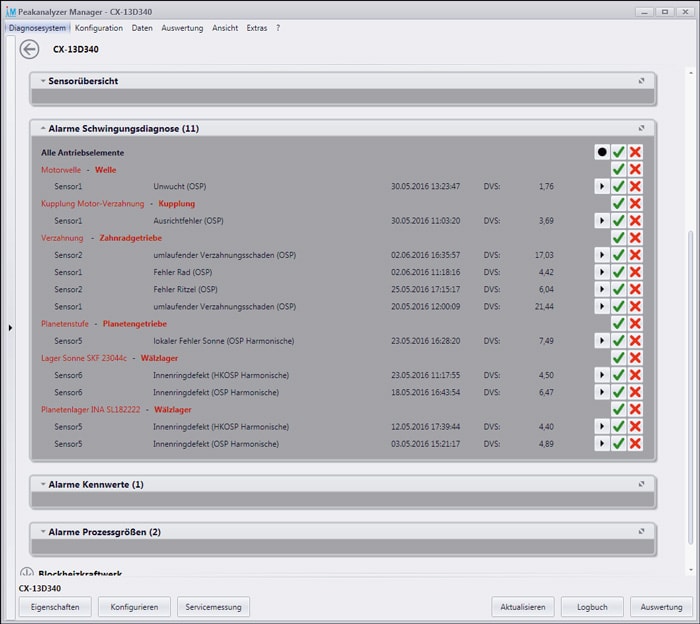

How an alarm looks like

An alarm is displayed at the Peakanalyzer and if necessary also at external platforms, like a control centre.

Abnormalities and the associated significance values are shown in an alarm overview in tabular form. The user does not need any diagnostical experiences to get valuable diagnosis results.

A diagnosis expert can check the detected irregularities in the order spectra and in the envelope curve spectra.