-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

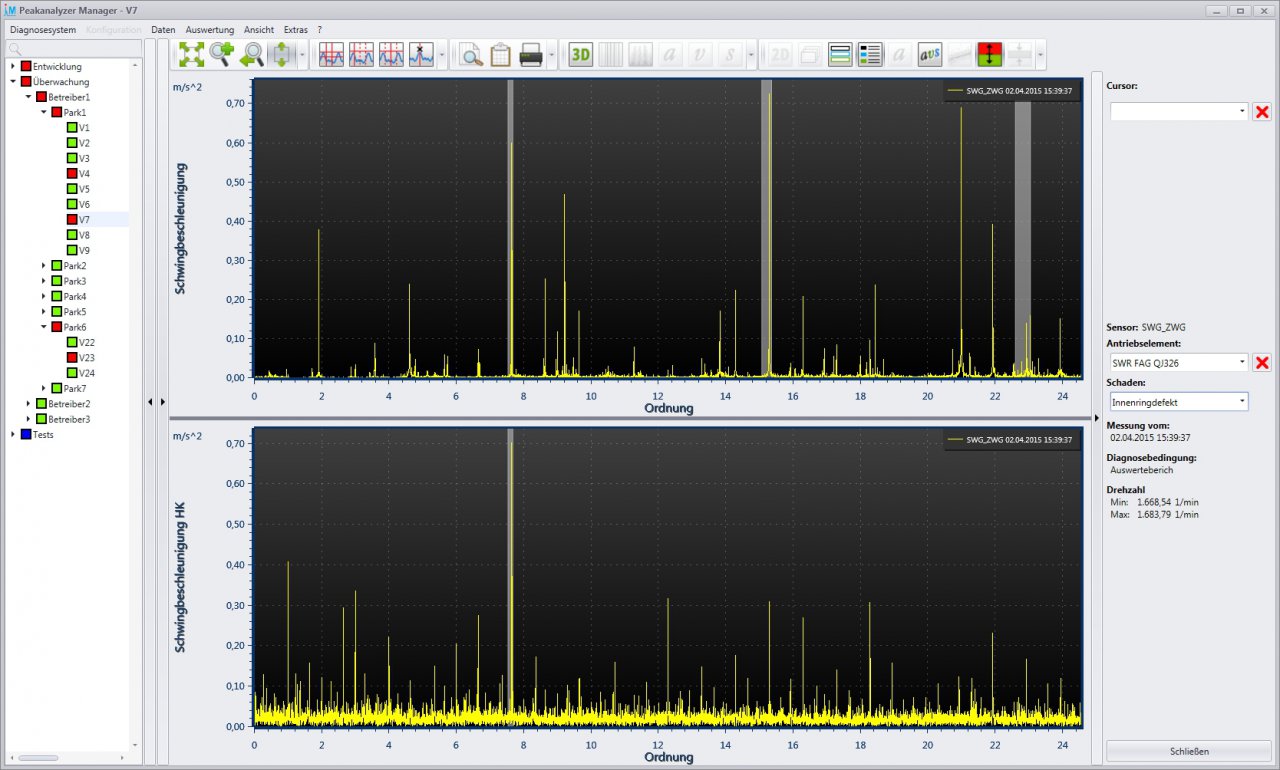

Diagnostic Tool - Analysis of External Data

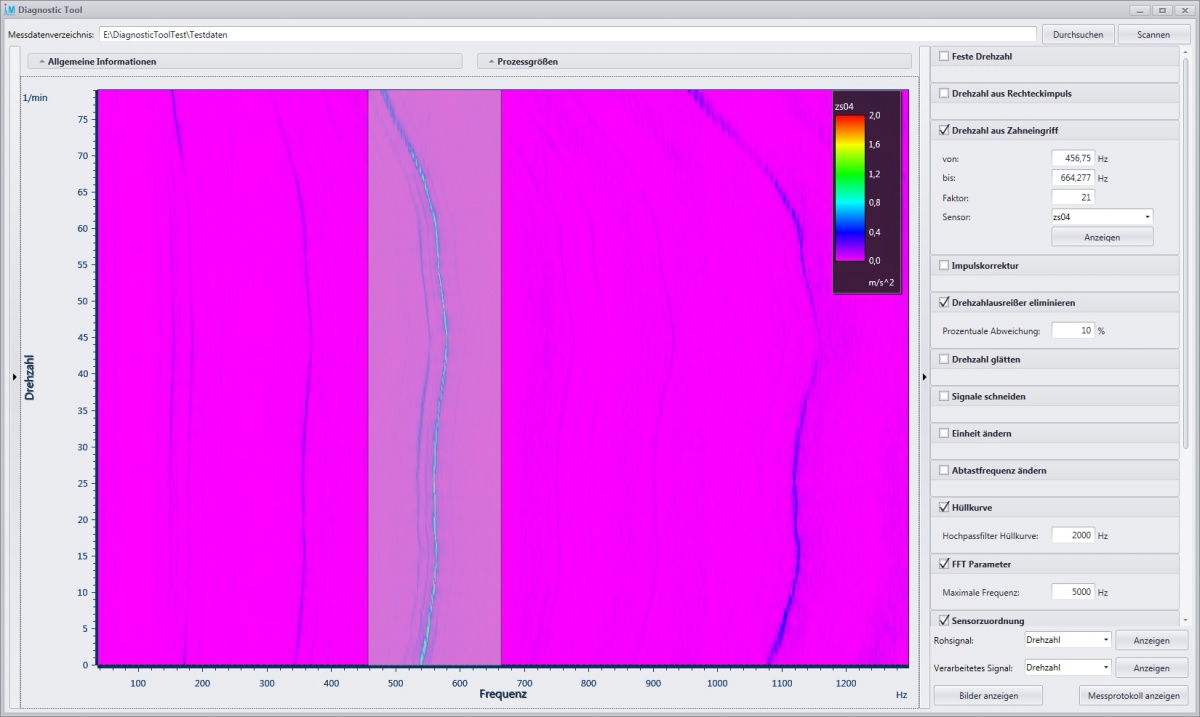

With the Diagnostic Tool, measured data can be calculated and analyzed by the PeakStore5 as well as by other measuring systems. In this case, according to configuration, frequency and envelope frequency spectra as well as order and envelope order spectra are formed at existing speed. In addition, the RMS values of the vibration velocity and vibration acceleration are calculated by all sensors. In the fully licensed version, the fully automatic diagnosis is performed on the basis of the kinematic data as with the Peakanalyzer. Found abnormalities of drive elements are reported without the intervention of an operator. In a later release, a report generator will also be available to create a complete diagnostic report. The fully licensed Diagnostic Tool can read in addition to the measured data of the PeakStore5 the following data formats:

- PeakStore200, PeakStore400, PeakStore410

- DasyLab

- Famos

- Diadem

Signal conditioning tools:

- Define fixed speed

- Generate speed from rectangular pulse

- Generate speed from meshing

- Pulse correction

- Eliminate speed outlier

- Smooth the speed

- Cut signals

- Change unit

- Change the sampling frequency

- Change the envelope shaping filter

- Change FFT parameters

- Change sensor assignment