-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Drum Couplings

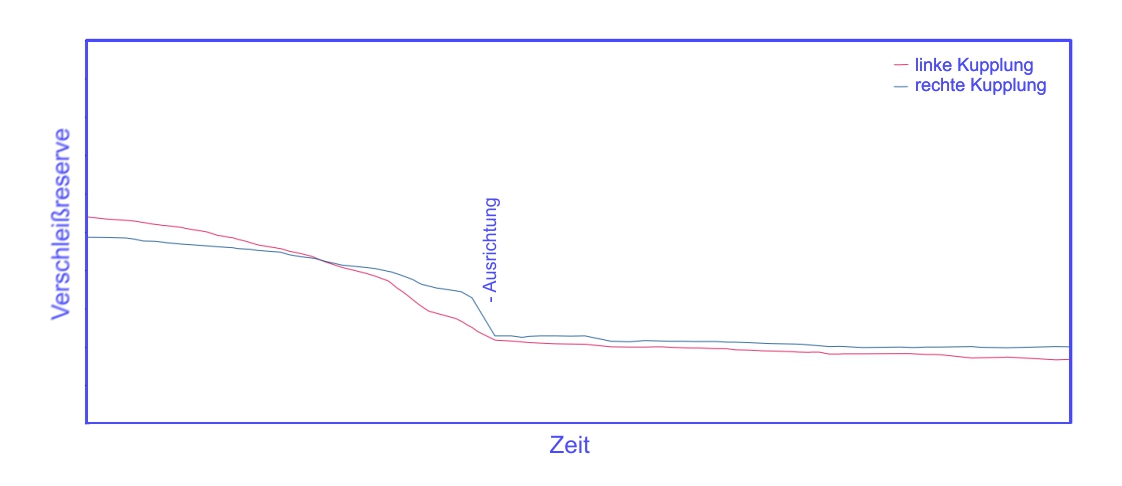

Drum couplings are used for frictional rotation transmission between a drive and a cable drum. This special coupling shape tolerates misalignment due to deflection of the cable drum. However, barrel couplings are subject to wear processes, knowledge of which is absolutely necessary to maintain operational safety.

Measuring wear in a conventional way is only possible at discrete points in time, requires a lot of personnel and always involves intervention in the production process. This justifies a technical solution that GfM provides with the Peakanalyzer, the online condition monitoring system.

In fact, only the rotation of the clutch housing and clutch hub is measured. The measurements are carried out with high resolution. In this way, angular changes can be recorded that directly correlate with the state of wear.

The installation is extremely easy and can be completed in a short time. Retrospective installation on existing systems is also possible without any problems.