-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Condition Monitoring Services

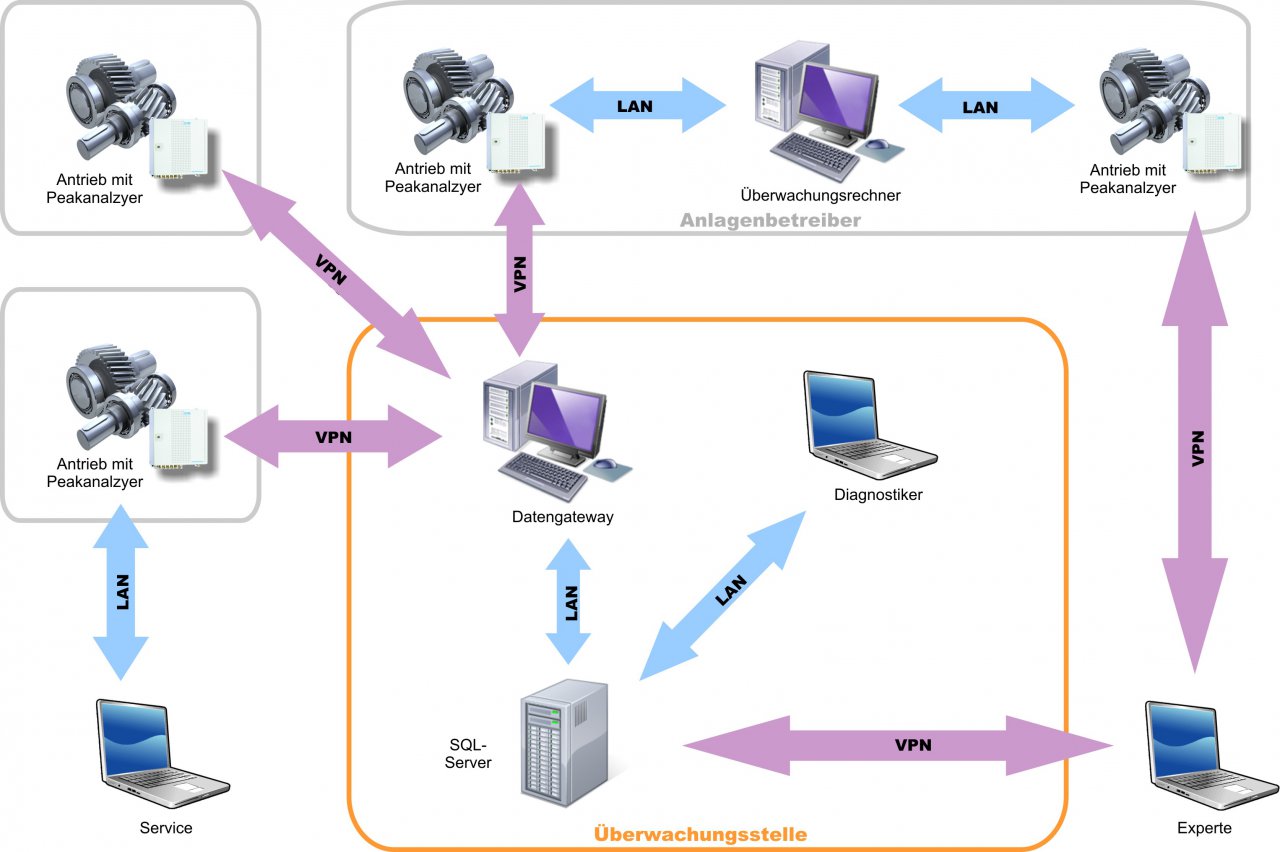

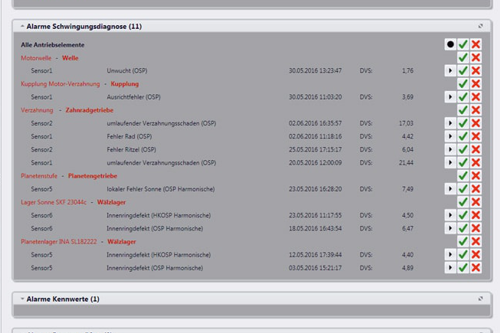

Monitoring Service for Online CMS

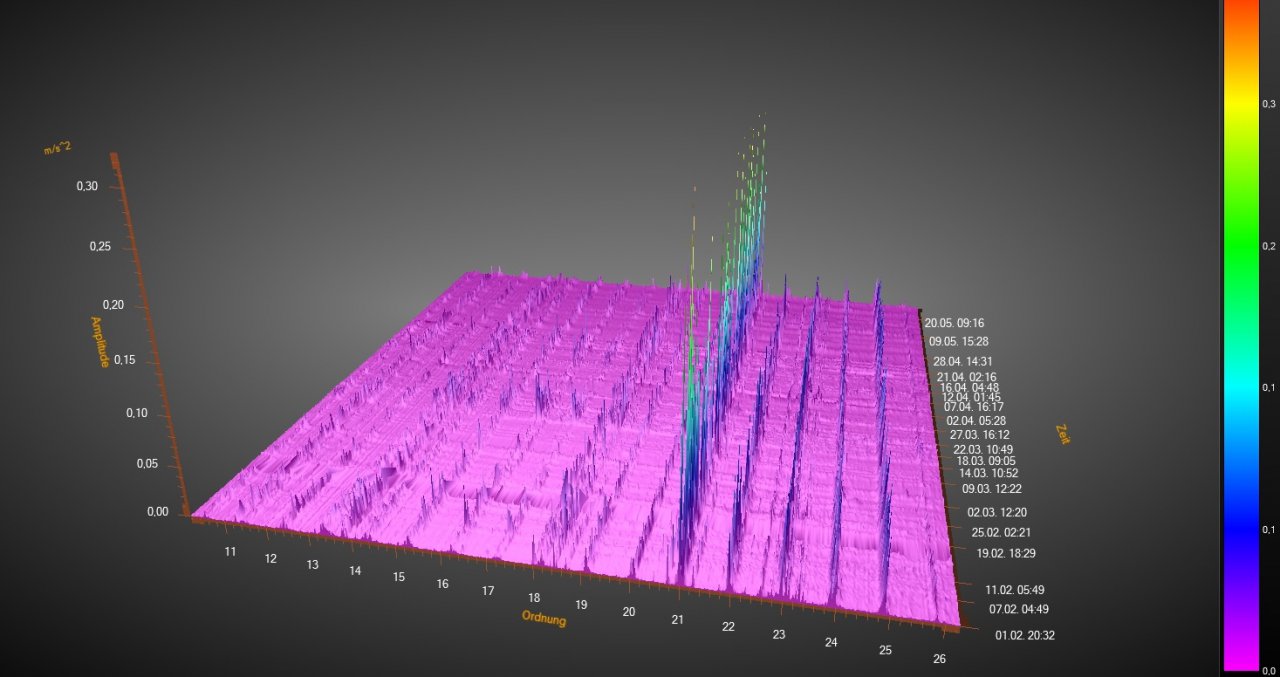

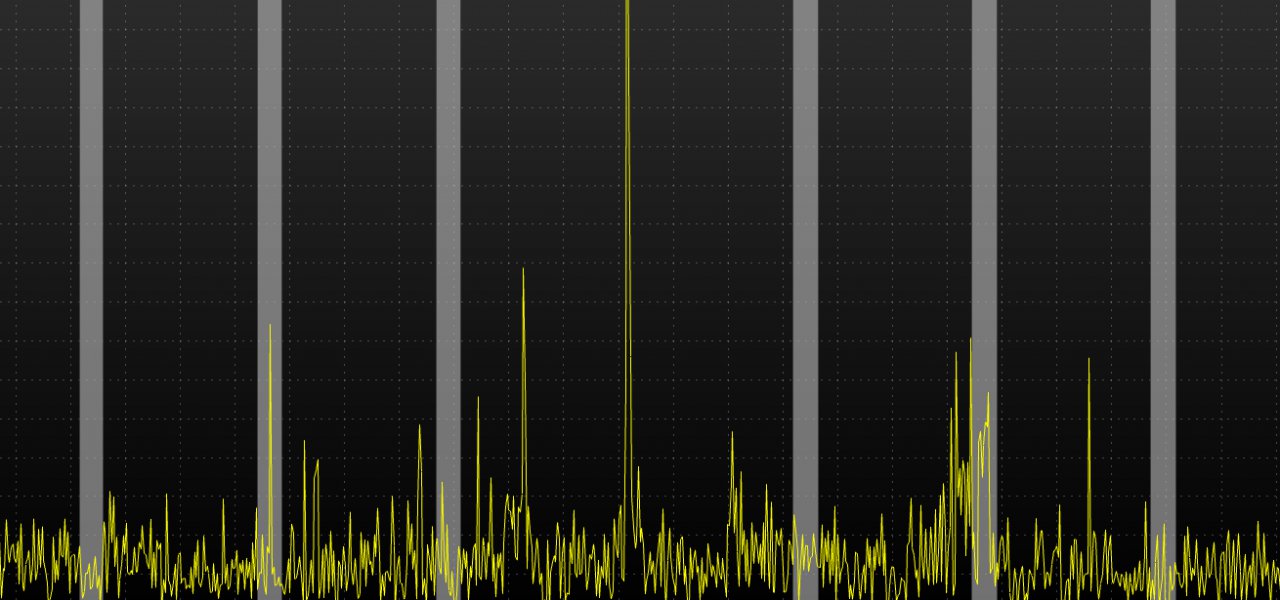

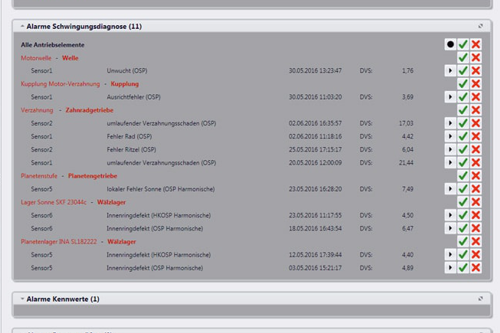

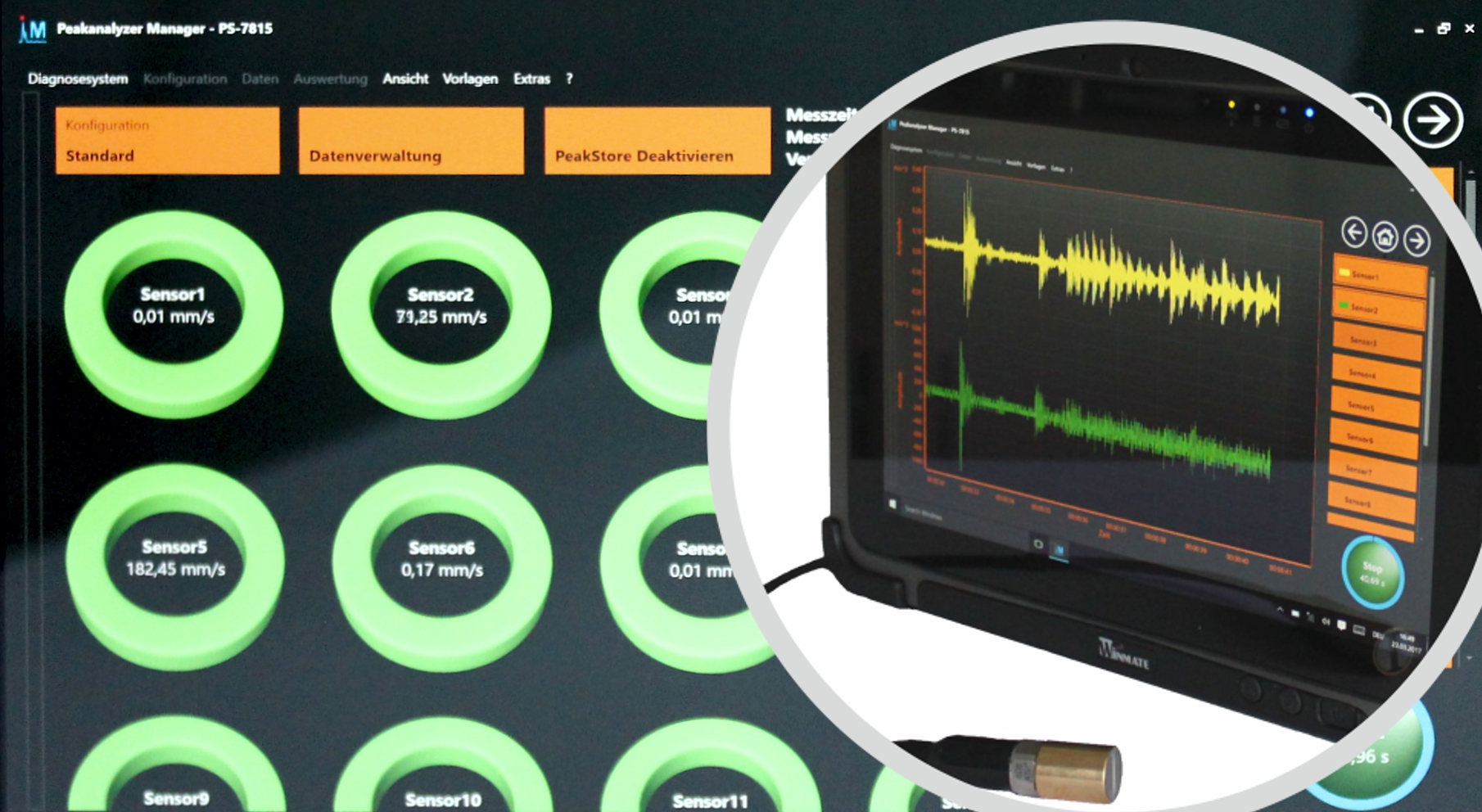

Offline Vibration Diagnosis of Drivetrains

Torque Measurement

Troubleshooting

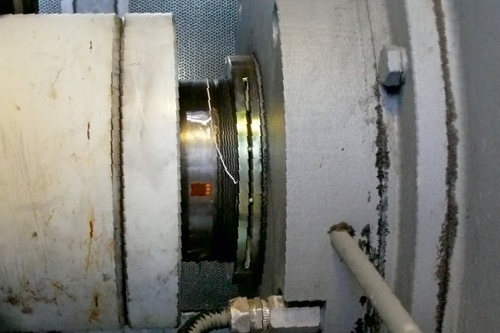

Gearbox Inspection and Video Endoscopy

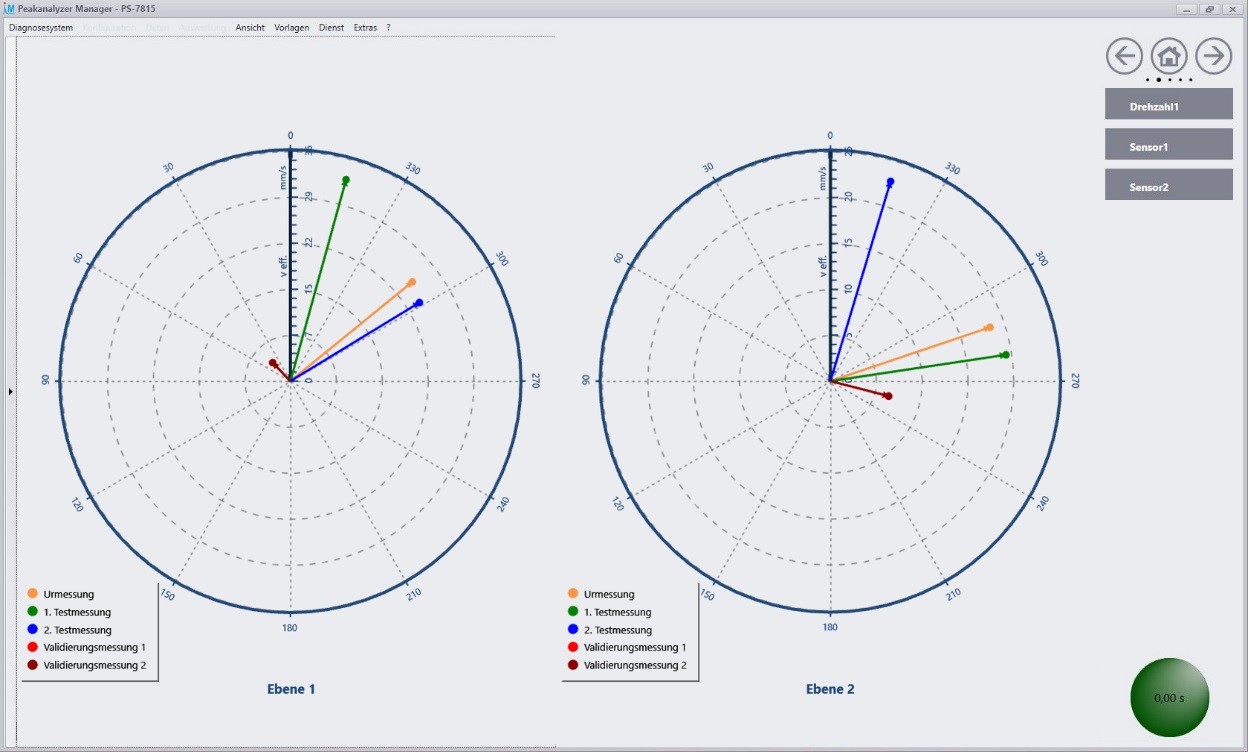

Field Balancing

Blade Bearing Diagnosis on WTGs

Foundation Monitoring on WTGs

Revision / Repair / Supervising

GfM Gesellschaft fuer Maschinendiagnose mbH offers range of machine diagnostic and metrological services for the drive engineering. These benefits are interesting for operators of drives, as well as for manufacturer of machinery, equipment and drive components.

The preservation of the fuctional capability of the technical equipment is very important for the operator of drives. At regular intervals, measurements and machine diagnostic tasks contribute to detect damages at an early stage and they are the basis for a predictive maintenance. Only in this way a consequently optimized machine performance and therefore a benefit for the plant operator realizable.

For manufacturers of drive components, metrological and machine diagnostic services are interesting when there are quality issues assumed by the end customer. Often the measurement of verification of the actual technical situation is less expensive than over months protracted negotiations between the after-sales area on the one and the investment sector on the other hand.

For operators as well as for construction departments of drive engineering manufacturer – e.g. in the case of plant modifications – metrological services to determine the actual load situation of drives are interesting. This counts in particular if the load contains strong dynamic parts.