-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

Integrated Peakanalyzer

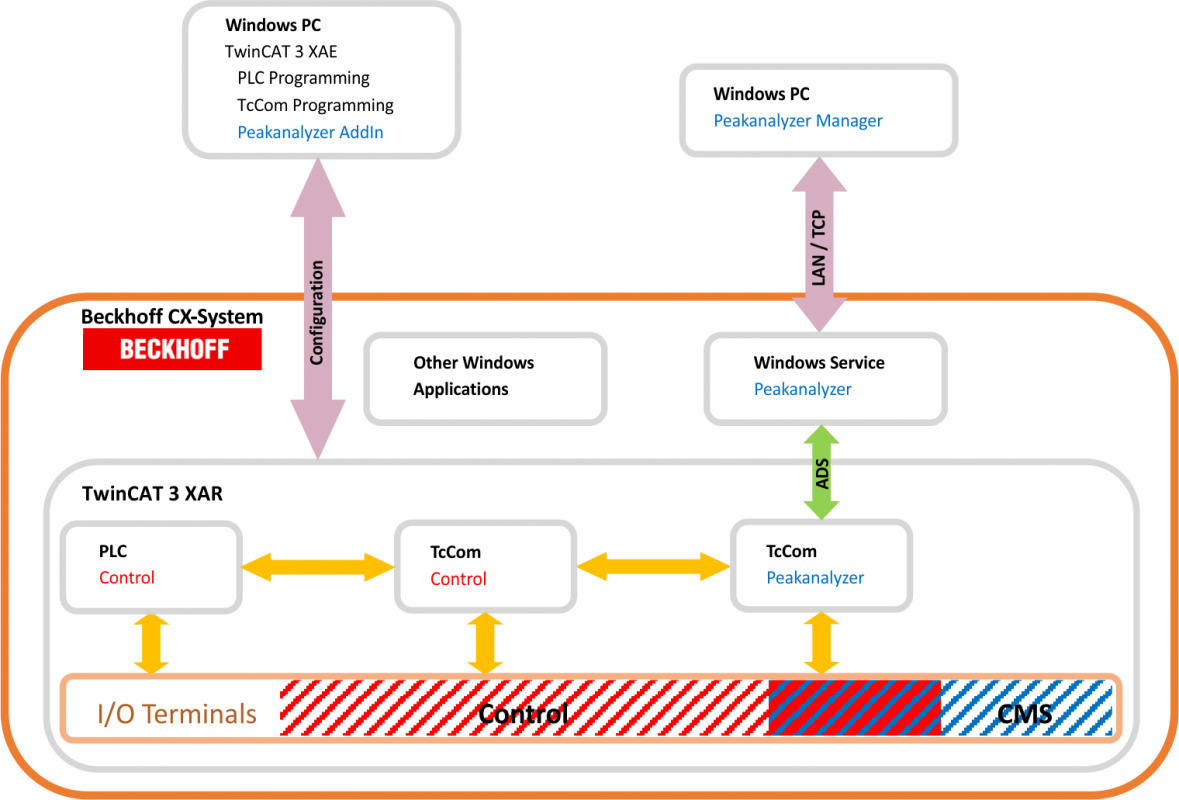

The Integrated Peakanalyzer is a software license for a high-efficiency, frequency-selective condition monitoring system based on existing or user-installable hardware.

With the Integrated Peakanalyzer, irregularities in the drive train, i.e. anomalies on shafts, couplings, gears and rolling bearings can be detected reliably and early. The analysis is realized by high-frequency detection of the vibrations, formation of order spectra and envelope order spectra and the automatic detection of significant spectral components corresponding to damage patterns.

The prerequisite is the presence of a Beckhoff TwinCAT 3 environment including the necessary analog input terminals and sensors. Compared to a autarkic system, there is a direct cost advantage, since the industrial PC used for the control can also be used for the Peakanalyzer. Likewise, the existing communication infrastructure can be used to configure the Peakanalyzer or to download the data.

Information already present in the control unit, such as speed, wind speed or electrical power are usually taken directly into the Integrated Peakanalyzer. No additional sensors need to be planned for these measurements. In addition, diagnostic results can be made directly accessible to the controller.

The Integrated Peakanalyzer runs in a separate task on the TwinCAT 3 environment and only accesses signal input terminals that are assigned to the Peakanalyzer. The tasks serving the control unit remain unused.

The hardware configuration is carried out via an additional plug-in, which is fully intedrated in the TwinCAT 3 development environment and in a few steps enables an assignment of the signal input terminals to the Peakanalyzer. The further configuration of the sensors and of the drive train is carried out with the Peakanalyzer Manager software.