-

Entry date 24.07.2025

Condition monitoring at HUSUM WIND 2025

-

Entry date 16.07.2025

Condition monitoring saves system operators a lot of money

-

Entry date 27.01.2025

Drum coupling monitoring - Automatic condition monitoring on cranes

-

Entry date 18.10.2024

Condition Monitoring and Artificial Intelligence

-

Entry date 15.12.2023

Condition monitoring at maintenance Dortmund on February 21st and 22nd, 2024

PeakStore5 – Mobile Condition Monitoring on up to 12 Channels

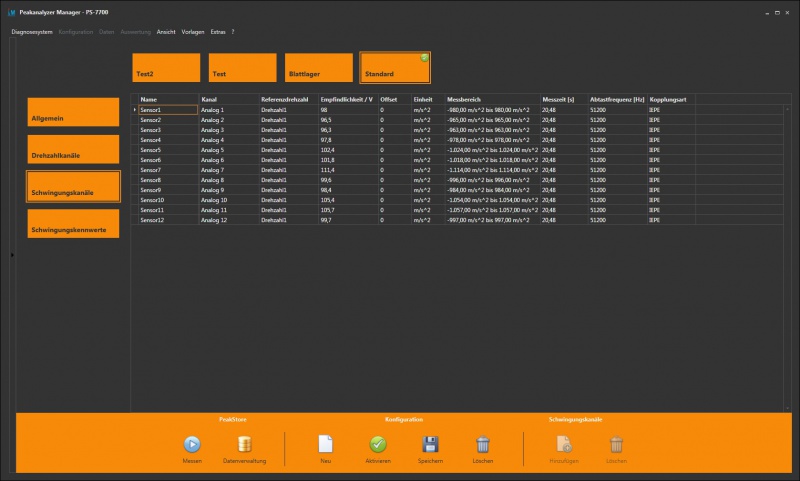

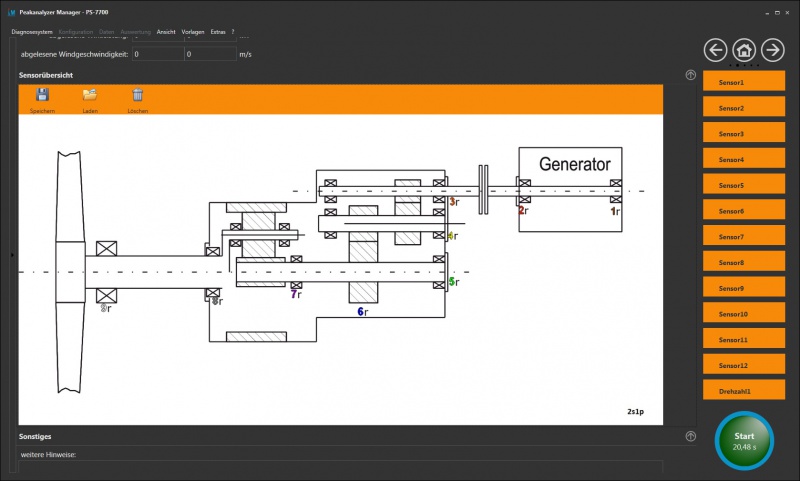

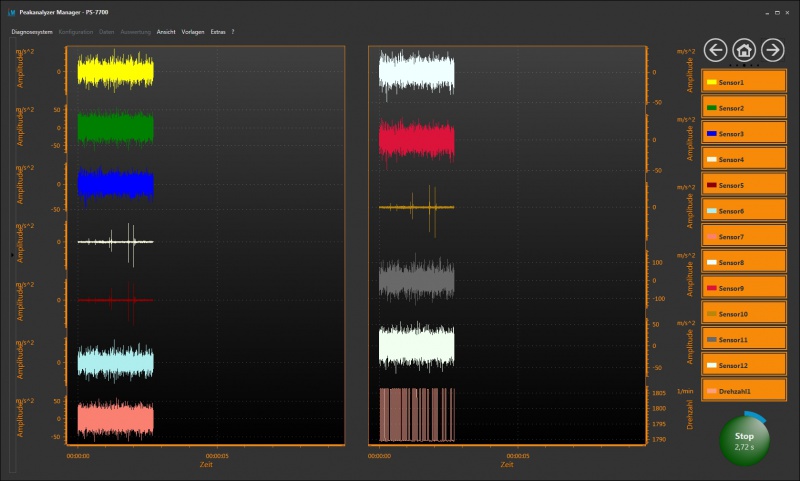

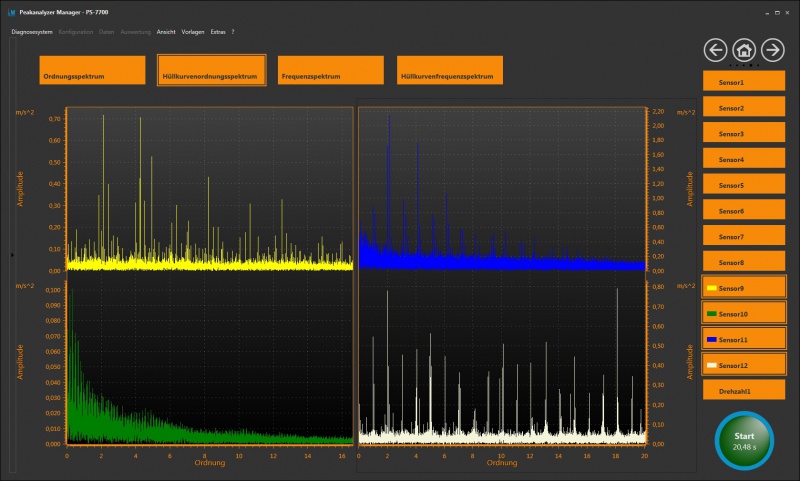

Vibration measurements can easily be performed by the PeakStore5. The sensors have to be attached with magnets at the engine. Now, the PeakStore5 has to be started. The whole process just takes a few minutes. Then, you simply put back the sensors in the case again and log the measurements and is done. The data collection is carried out with up to 12 vibration channels and one speed channel. At many drives, it is no longer necessary to implement sensors, to operate all necessary measuring positions. Furthermore, the PeakStore5 can be remote controlled via an app on a smartphone, so that no staff needs to be directly near the machine during the measurement. Diagnosis is done preferably by order analysis. So, speed ripples have no influence, and the measuring results are absolutely reliable. The operation is realized by a full-fledged integrated tablet PC and the software PAM. There you can look at the data directly and analyze it locally. But you can also store additional information such as photographs and measurement protocols. Or you ship all data directly to a service provider for analysis. Measurement times of 1.5 seconds up to 164 seconds and indefinite measurement times as well can be set. In case of the indefinite measurement time you can record with 12 channels, each with 51.2 kHz sampling rate, about 4 hours of measurement data.

Video: Create a configuration in PeakStore5

Video: Measurement data recording with the PeakStore5

You can also find our learning videos on our youtube channel.

Excursus on the sampling frequency

A sampling frequency of more than 50 kHz seems to be rather high. However, sinusoidal vibrations are detectable up to a frequency of 25 kHz. In practice, this value will be lower, because of the characteristic of the antialiasing filter.

Envelope analysis is used for the bearing diagnosis. Envelope analysis is capable to extract the force pulses, which are generated through bearing damages. These force pulses are linked with the natural vibrations of the whole system via convolution.

This natural vibrations of the system are the really carriers of the diagnostic information from the damage to the acceleration sensor. The quality of this natural vibrations has a significant

influence on the quality of the diagnosis, itself.

The frequencies of these natural vibrations are determinable, but usually different from machine to machine. In practice, the best diagnosis results are achieved, through broadband measurements. This results in the relatively high sampling frequency of 50 kHz of the PeakStore5.